Though Somerset House, its creative community and our visitors have been kept apart over the last few months, Makerversity - a community of emergent maker businesses - have been keeping busy behind the scenes producing much needed PPE for frontline workers.

We got in touch with Makerversity's CEO Fiona Dent and the team to learn more about the project.

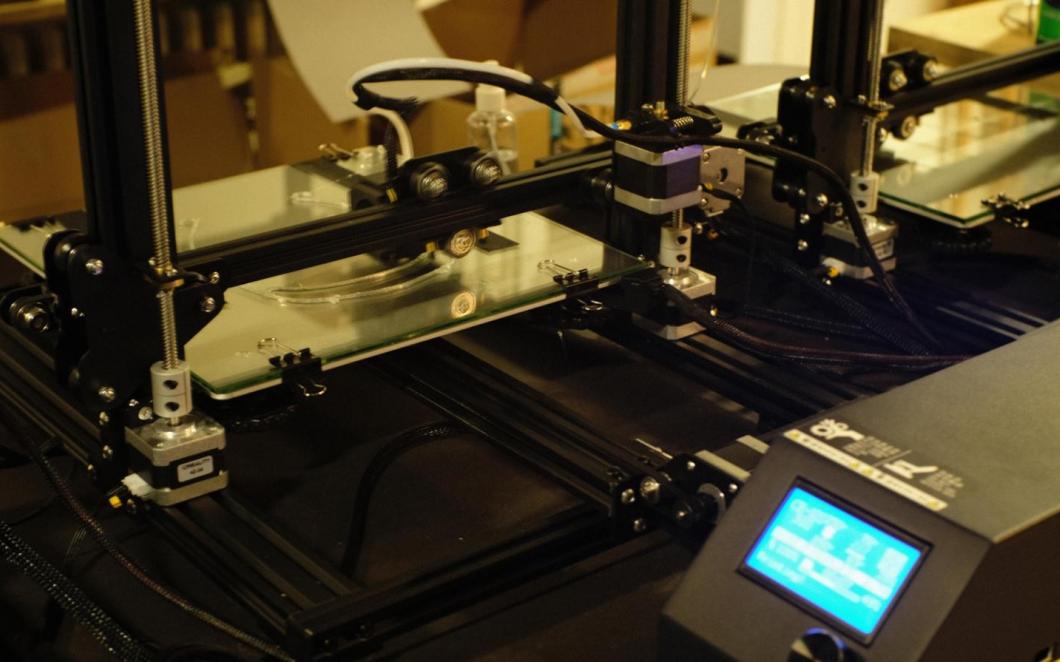

How did the project begin and how did you go about setting up the 3D print farm?

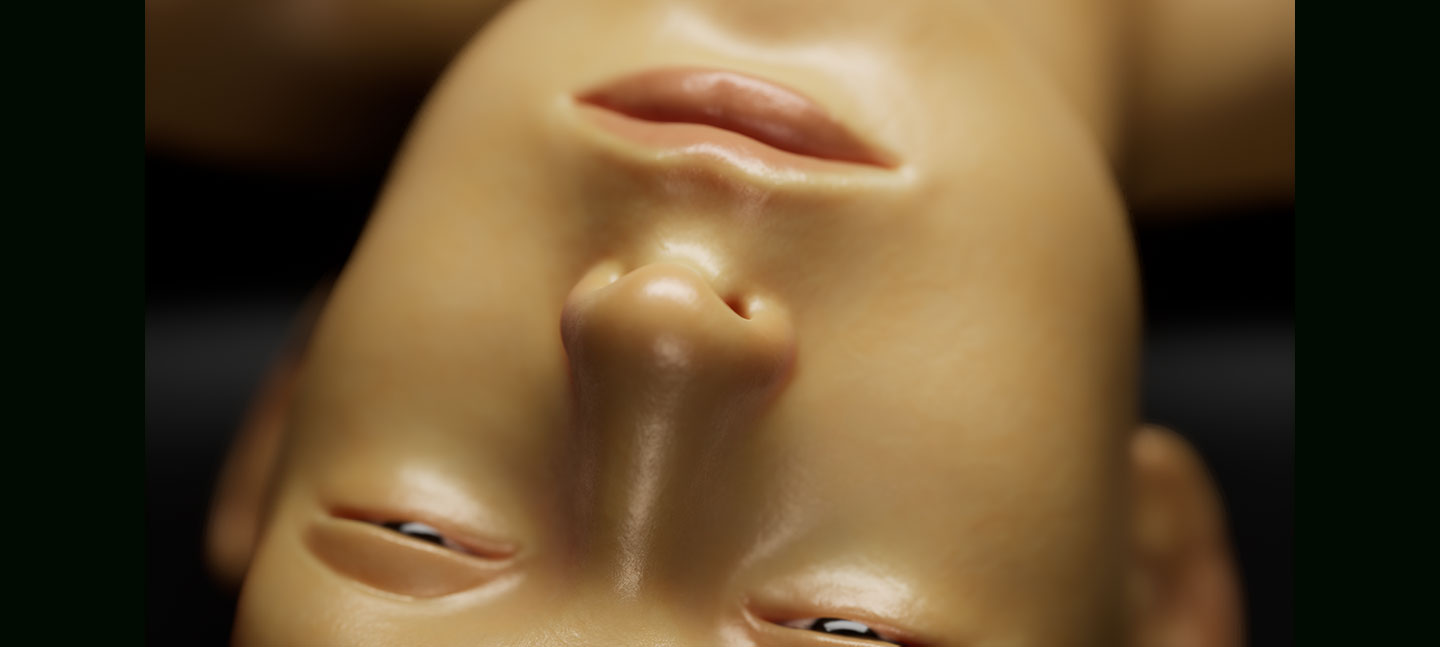

Makerversity member Nate Petre, who came up with the idea for the PPE 3D print farm, was previously a researcher at Imperial College’s Dyson School of Design Engineering specialising in Digital Disruptive Manufacturing. Backed by funding from NASA, he developed the world’s first fully compostable 3D-printed surfboard. After leaving Imperial, Nate embarked upon extensive global travels, helping small communities 3D print scarce resources, such as water pumps and prosthetic limbs. All this experience was about to become even more relevant.

Nate joined Makeversity a matter of weeks before the pandemic took hold in Europe. He quickly understood that the application of Digital Disruptive Manufacturing, micro-manufacturing using 3D printer ‘farms’, had a new imperative. The Covid-19 outbreak had already forced China into lockdown, a severe crisis was beginning in Italy and the pandemic was about to sweep across Europe. As Nate observed: